Project

Scientific questions and technological challenges

- The central scientific challenge for high capacity next generation batteries is to establish how these parasitic processes proceed (mechanism and kinetics) and how they depend on materials interface properties (chemistry, crystal orientation, surface termination). BatteryNL will develop simplified model systems and investigate these with novel and state-of-the-art operando techniques to gain vital comprehensive understanding.

- The subsequent challenge is to translate this understanding into strategies that enable control of those interface processes, by designing the interfaces, leading to selected scalable materials and interface engineering solutions that will lead to safer and more efficient batteries.

- The successful integration of new generation battery materials and technologies requires accurate analysis of costs and sustainability developments, detailed consideration of safety aspects, technology integration through collaboration with manufacturers and knowledge institutions, interaction with stakeholders. Battery experts have to be trained. Interrelated scientific, technological and societal challenges need to be addressed by academics, technologists, public associations, private/public parties and stakeholders within the framework and in connection to European initiatives.

Main objectives

Objective 1

Objective 2

Objective 3

Objective 4

Objective 5

Work packages

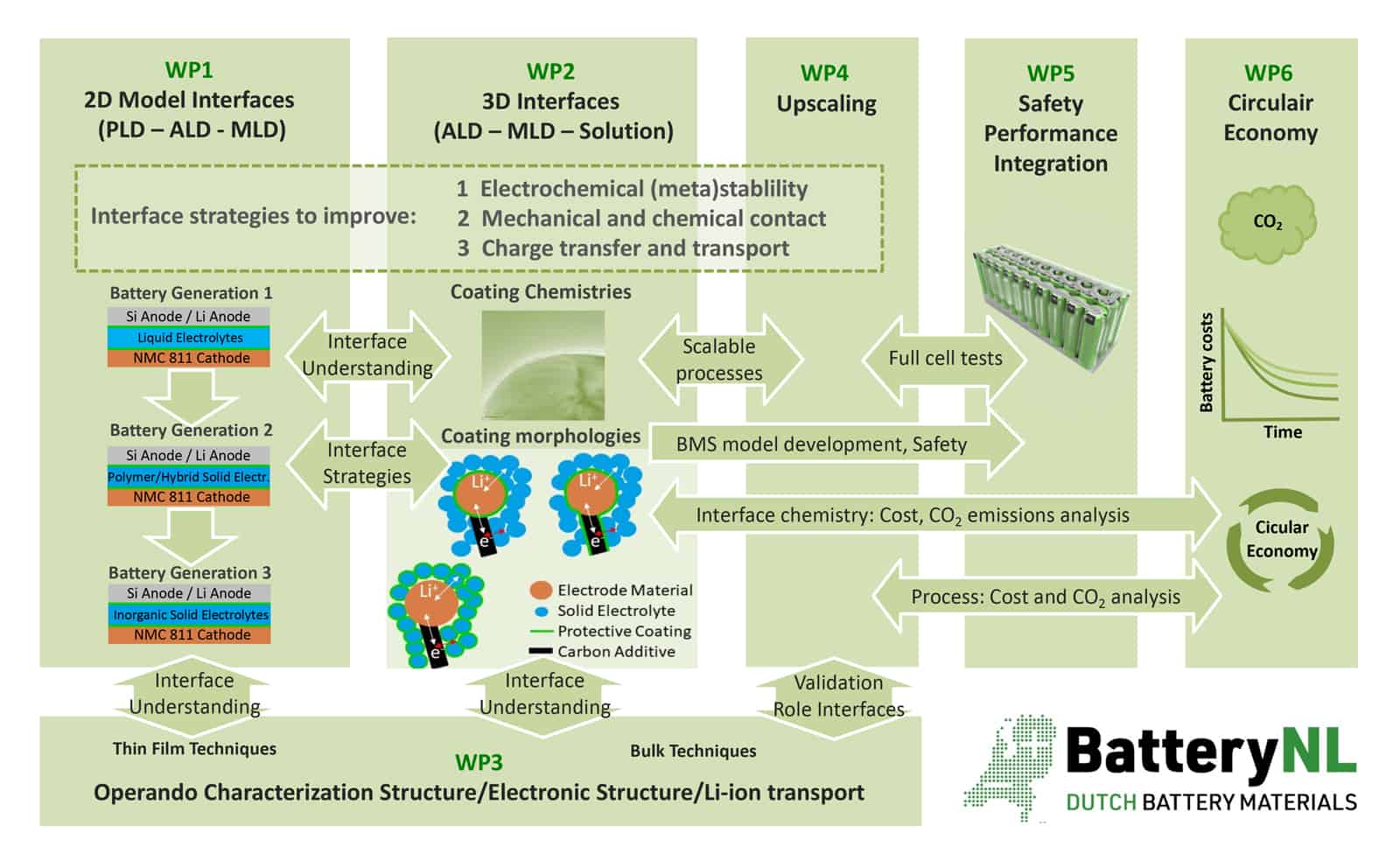

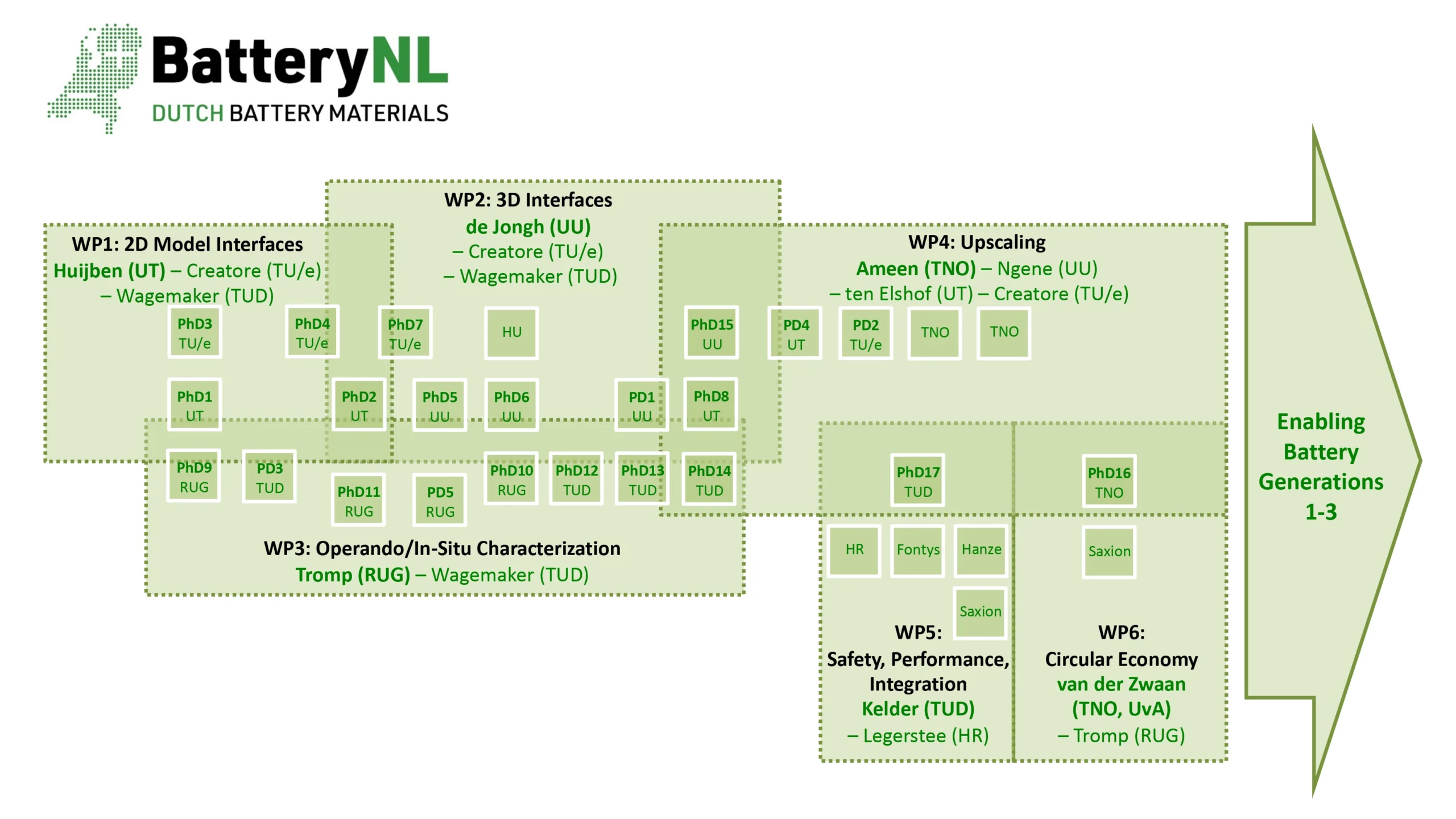

The project is organized in six technical work packages (WP1-6), one work package involving collaboration, outreach and the creation of a Battery NL network (WP7), and one work package for the project management and data management (WP8).

WP1 > 2-dimensional Li-ion battery model systems: understanding interface reactions and strategies towards stable interfaces

Objectives:

- Synthesize 2-dimensional, thin film model systems consisting of the most promising anodes, cathodes and electrolytes for Li-ion battery generations 1-3.

- Gain insights into the parasitic reactions occurring at the anode/electrolyte and electrolyte/cathode interfaces and how these originate from interface properties defined by the model systems.

- Develop interface architectures which suppress/prevent the parasitic reactions, therefore leading to electrochemically and mechanically stable interfaces, along with efficient charge transfer and transport.

WP2 > Development of Interface Strategies and translation from 2D to 3D

Objectives:

- Develop 3D model electrode systems.

- Translate the most promising interface strategies developed in 2D in WP1 to be applied in 3D structured systems, building on these 3D model systems.

- Understand the effectivity of interface strategies employing liquid (Gen1), polymer-based (Gen2) and solid-state (gen3) electrolytes using the advanced techniques of WP3.

- Select the most promising interface strategies and start translating them to real battery systems and upscalable techniques that will be further developed and employed in WP4.

WP3 > Operando Characterization

Objectives:

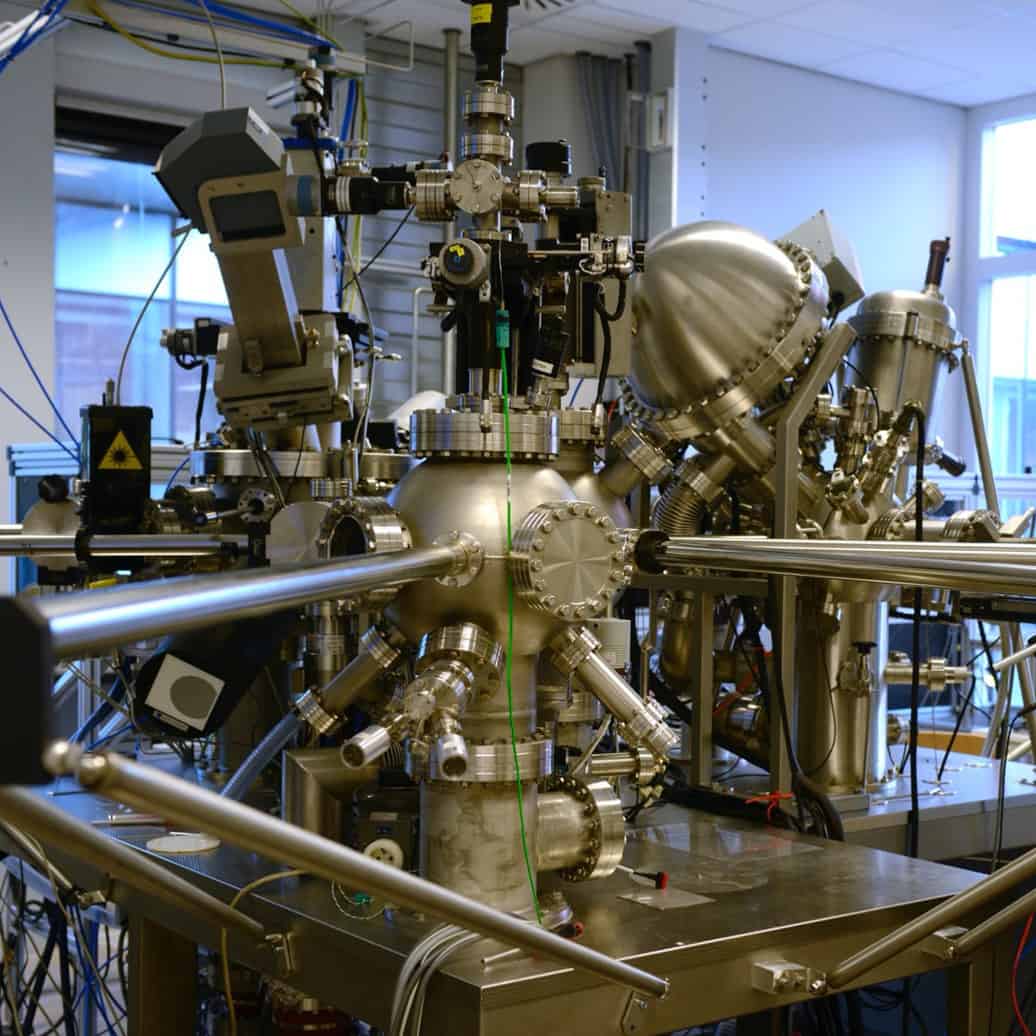

- Development of surface- and interface-sensitive operando techniques and methods.

- Understand interface reactivity as well as diffusion phenomena in operating batteries.

WP4 > Upscaling strategies for interface engineered battery materials

Objectives:

- Investigate and develop concepts and processes for large-scale fabrication of the interface-engineered battery materials, researched within WP1 & 2, thereby stepping towards potentially upscalable materials and processes relevant for industry.

- Focus on anodes (Si and Li metal), cathodes (nickel rich layered transition metal oxides: NMCs) and electrolytes (solvent-free polymer-based, inorganic electrolytes based on oxides, halides, sulfides and complex metal hydrides, and hybrid electrolytes based on polymer-inorganic combination).

WP5 > Safety, Performance and integration

Objectives:

- Identify the relevant safety issues related to Li-ion batteries.

- Create a generic model to be used for the development of a BMS.

- Translate kinetic data from WP1-4 into the BMS model.

- Develop the electronics for the BMS.

- Analyse commercial batteries and project cells for input data for the above objectives as well as for the validation of those.

WP6 > Socio- and Techno-economic Studies

Objectives:

- Socio-economic studies.

- Development of learning curves for Li ion batteries.

- Techno-economic analysis.

- Energy system modelling, in order to assess overall competitiveness, also with respect to alternatives like petrol and H2.

WP7 > BatteryNL network, collaboration and outreach

Objectives:

- Set up the BatteryNL network.

- Organize and stimulate interaction and communication between the partners and with the stakeholders.

- Disseminate the results.

- Coordinate the education of the human capital on the full chain of battery technology.

Overview research topics of PhD candidates and Postdocs

PhD 1 - UT - Han Xue

Ph.D. thesis “Thin film model systems of high voltage cathode materials”

My research will focus on the development and analysis of thin film model systems of high voltage cathode (e.g. Ni-rich layered metal oxides and spinel oxides). The objective is to gain insights into the parasitic reactions occurring at the cathode-electrolyte interface and how these originate from interface properties defined by thin film model systems.

Pulsed laser deposition (PLD) will be used to create thin film model systems of cathode exhibiting atomically flat surfaces and tuneable lattice planes for investigating the reaction mechanisms at the interface between the cathode and the (liquid or solid) electrolyte. Moreover, the thin film model provides the possibility to study mechanical failure and parasitic electrochemical reactions occurring at the interface without the effects of binders and conductive materials.

Insights will be generated by electrochemical testing (e.g. cyclic voltammetry, impedance spectroscopy) as well as in situ and operando techniques (e.g. XRD, XPS), on how the electrochemical and mechanical behavior of the cathode-electrolyte interface is affected by the cathode chemistry and lattice plane, which will provide a perspective on concepts and processes for large-scale fabrication of the interface engineered battery materials.

PhD 2 - UT - Ivan Trefilov

Ph.D. thesis “Thin film model systems of high-capacity anode materials for lithium-ion batteries”

Anode is a crucial component of widely used lithium-ion bateries (LIB), and it significantly affects their characteristcs. The commercially utlized graphite anode materials do not meet growing demands in high-performance batteries due to low theoretical gravimetric and volumetric capacity. Over the past twenty years, many works have been dedicated to studying high-capacity anode materials as alternatives to graphite. Although the capacity of that materials can be ten times higher than that of graphite (e.g., as it is for silicon), their use is still hindered by the rapid degradation of the materials during battery operation.

This Ph.D. project will tackle developing and analyzing thin-film model systems of high-capacity silicon-based anode materials. The silicon was chosen because it is a highly abundant, low-cost material with a high capacity value of 3579 mAh g-1 (Li15Si4). The model systems will be used for studying the parasitic processes on the anode-electrolyte’s interfaces with the electrochemical methods, surface morphology, and compositional analysis methods in in-situ and operando conditions. These results will help to determine the reasons behind modern high-capacity anode materials’ degradation over cycling and suggest strategies for designing high-capacity anode materials with improved cycle life characteristics.

PhD 3 - TU/e - Meike Pieters

Ph.D. thesis “Cathode and cathode/electrolyte interface engineering by ALD for Li-ion batteries”

The key problem in the development of high capacity next generation batteries lies at the interfaces between the electrodes and the electrolyte. Using 2D model systems fabricated by atomic layer deposition (ALD), I investigate how the chemical composition and crystallographic properties of high-voltage cathodes affect the interface with (liquid and solid) electrolytes. Secondly, I engineer strategies to create (electro-)chemically and mechanically stable cathode/electrolyte interfaces, such as coating the cathode with an ultra-thin artificial cathode-electrolyte interphase (CEI).

PhD 4 - TU/e - Vacancy

Vacancy

PhD 5 - UU - Karan Kotalgi

Ph.D. thesis “Passivated – 3D model electrodes: Cathode-electrolyte interphase engineering for Lithium-ion batteries”

In recent years, research in lithium-ion batteries has grown to make batteries with higher energy and power density. The energy and power loss of batteries are a serious problem. This loss was understood after probing the surface layer of the anode under a microscope revealed the existence of the Solid-electrolyte interface (SEI). This layer revealed the link to capacity loss and voltage fading of batteries[1]. Prof. Goodenough et al., showed in his work that a similar interface layer is formed at the surface of cathodes called the Cathode-electrolyte Interface (CEI)[2].

Originally, CEI was thought to form at voltages above the cut-off potential of batteries, but new studies suggest CEI may also form at voltages below 4.2V[3]. The reason for increasing the cut-off potential is to extract more lithium from the cathode structure, which in turn increase the output of the batteries[4]. Unfortunately, this also degrades the cathode structure, which leads to batteries failing with shortening of their lifespan[5].

I will be working to identify the components of CEI formed on different Ni-rich cathodes, and to coat a thin-film on the surface of the cathode. This surface coating with prevent the degradation of the cathode material. Surface coating techniques like Atomic layer deposition (ALD), Molecular layer deposition (MLD), and Pulse layer deposition (PLD) would be used in collaboration with TU Delft, TU/e, UT, and RUG. Techniques such as XRD, XPS, SEM, TEM, FTIR, Physisorption, and electrochemical characterization techniques such as CV, CCCD, and EIS can help to understand the CEI.

References:

[1] An Overview on the Advances of LiCoO2 Cathodes for Lithium‐Ion Batteries, Advanced Energy Materials 11(2), Wiley 2021, 1614-6832, 10.1002/aenm.202000982

[2] K. Mizushima, P.C. Jones, P.J. Wiseman, J.B. Goodenough, LixCoO2 (0<x<-1): A new cathode material for batteries of high energy density, Materials Research Bulletin, Volume 15, Issue 6, 1980, Pages 783-789

[3] Xu, J. Critical Review on cathode–electrolyte Interphase Toward High-Voltage Cathodes for Li-Ion Batteries. Nano-Micro Lett. 14, 166 (2022).

[4] Daxian Zuo, Guanglei Tian, Xiang Li, Da Chen, Kangying Shu, Recent progress in surface coating of cathode materials for lithium-ion secondary batteries, Journal of Alloys and Compounds, Volume 706, 2017, Pages 24-40

[5] Face to Face at the Cathode Electrolyte Interphase: From Interface Features to Interphase Formation and Dynamics, Advanced Materials Interfaces 9(8) Wiley 2022, 2196-7350

PhD 6 - UU - Jonas Hehn

Ph.D. thesis “Interface effects in polymer-based hybrid electrolytes for all-solid-state lithium ion batteries”

Researchers have been focusing on the development of novel Lithium-ion conductive solid electrolytes for decades. These materials are intended to replace the flammable and therefore unsafe liquid electrolytes used in conventional Li-ion batteries. Generally, there are two types of solid electrolytes: inorganic solid electrolytes that can have, for example, high Li-ion conductivity but poor interfacial compatibility with the electrodes, and on the other hand there are elastic polymer-based electrolytes which posses good interfacial compatibilities with the electrodes, but often poor ionic conductivity especially at room temperature. [1,2]

In this project, I combine the two aforementioned types of electrolyte to synthesize polymer-based hybrid solid electrolytes. For this purpose, I will investigate new but also already known Li-compounds in combination with polymers and inorganic fillers. The synthesized materials will be characterized using a variety of techniques. The goal is to understand how interface effects at the polymer-Li salt-filler material interfaces influence the ionic conductivity and other electrochemical properties of the hybrid electrolytes. Particular emphasis will also be placed on a detailed understanding of the interface formation and the interaction between the hybrid electrolyte and the electrodes. The fundamental knowledge is crucial to developing new electrolytes with tailor-made properties for applications in all-solid-state Li-ion batteries.

[1] X. Yu, A. Manthiram, Energy Storage Mater., 2021, 34, 282-300.

[2] Y. Zhai, G. Yang, Z. Zeng, S. Song, S. Li, N. Hu, W. Tang, Z. Wen, L. Lu, J. Molenda, ACS Appl. Energy Mater., 2021, 4, 7973−7982

PhD 7 - TU/e - Vacancy

Vacancy

PhD 8 - UT - Vacancy

Vacancy

PhD 9 - RUG - Maarten Jager

Ph.D. thesis “Understanding complex interphase effects in next generation Li-ion batteries”

The main aim of the research project is to unravel the complex interface processes in next generation lithium battery chemistries through novel and state-of-the-art methodologies targeted to newly developed (2D and 3D) model interfaces and representative battery morphologies.

PhD 10 - RUG - Jan Franse Brakenhoff

Ph.D. thesis “Understanding and controlling interface processes in Li-ion Batteries”

The main aim of the research project is to unravel the complex interface processes in next generation lithium battery chemistries through novel and state-of-the-art methodologies targeted to newly developed (2D and 3D) model interfaces and representative battery morphologies. More concretely, to develop advanced wet-chemical techniques and/or physical deposition techniques and their translation to 3D structures, applied to systems developed by us and other partners in the consortium. Ultimately leading to creating insights that explain the relevant interface processes, (electronic) structure changes and Li-ion transport, interface degradation mechanisms, including parasitic decomposition reactions, surface structure degradation, and transition metal leaching as a function of interface properties.

PhD 11 - RUG - Vacancy

Vacancy

PhD 12 - TUD - Vacancy

Vacancy

PhD 13 - TUD - Vacancy

Vacancy

PhD 14 - TUD - Anastasiia Lavrinenko

Ph.D. thesis “Modelling solid-state electrolytes and electrodes, focusing on the interfaces in next-generation lithium batteries”

Solid-state batteries are attracting considerable attention due to their increased safety, energy density, and wider range of operating conditions. Solid-state electrolytes show great promise to replace flammable liquid electrolytes typically employed in Li-ion cells. In this project, I will utilize computational techniques such as density functional theory, ab-initio, and classical molecular dynamics to investigate the electrolyte-electrode interfaces in solid-state batteries. The goal is to understand the fundamental mechanisms of interface formation and its impact on the ionic conductivity and other electrochemical properties of materials and battery systems.

PhD 15 - UU - Vacancy

Vacancy

PhD 16 - UvA - Vacancy

Vacancy

PhD 17 - TUD - Vacancy

Vacancy

PD 1 - UU - Vacancy

Vacancy

PD 2 - TU/e - Vacancy

Vacancy

PD 3 - TUD - Ajay Gautam

My research topic is “Understanding the Structural-Ionic Transport Relationship in Lithium Argyrodites as Solid Electrolytes for Higher Ionic Conductivity”

Argyrodite-based lithium-ion conductors are gaining attention as potential candidates for application in solid-state batteries on account of their high ionic conductivity and ease of mechanical processability. Despite this promise, several questions remain unanswered, particularly in the area of optimizing these solid electrolytes for even higher ionic conductivity.

In this project, I aim to explore the relationship between structure and ionic transport in various types of solid electrolytes, with the goal of better understanding how to regulate ionic conductivity.

PD 4 - UT - Vacancy

Vacancy

PD 5 - RUG - Luuk Kortekaas

My research topic is “Operando analysis of Li-ion battery performance”

My main focus is on developing novel (operando) battery performance assessment techniques at surfaces and interfaces. 2D single crystal thin film models from WP1 and realistic 3D electrodes from WP2 and WP4 will be investigated for their chemical composition, electronic structure, surface topography and Li-ion transport from nanometer to micrometer length scales. Advancing state-of-the-art operando spectroscopic techniques such as GI-XAS and operando XANES mapping will allow for more intricate analysis of battery systems and, moreover, pinpointing bottleneck problems in battery prototypes.